- Altilium uses EcoCathode™ technology to achieve high recovery rates of lithium (97%) and graphite (99%) from LFP batteries.

- The UK EV market is projected to see LFP battery use rise from 18% in 2027 to 25% by 2035, emphasizing the need for effective recycling methods.

- Altilium’s facility aims to process waste from over 150,000 EVs annually, strengthening the circular battery economy.

- The initiative addresses sustainability in battery disposal and meets regulatory demands for greener processes.

- Recycling is vital for preserving resources and supporting the future of electric mobility.

- As LFP battery demand grows, Altilium’s recycling efforts will help stabilize raw material costs and enhance the recycling industry.

- Sustainable recycling is crucial for achieving a greener automotive future.

In a bold leap towards sustainability, Altilium is transforming the electric vehicle (EV) battery landscape with its groundbreaking recycling operations for Lithium Iron Phosphate (LFP) batteries. Using innovative EcoCathode™ technology, the company can recover an astonishing 97% of lithium and 99% of graphite from discarded batteries, setting a new standard for resource conservation in the industry.

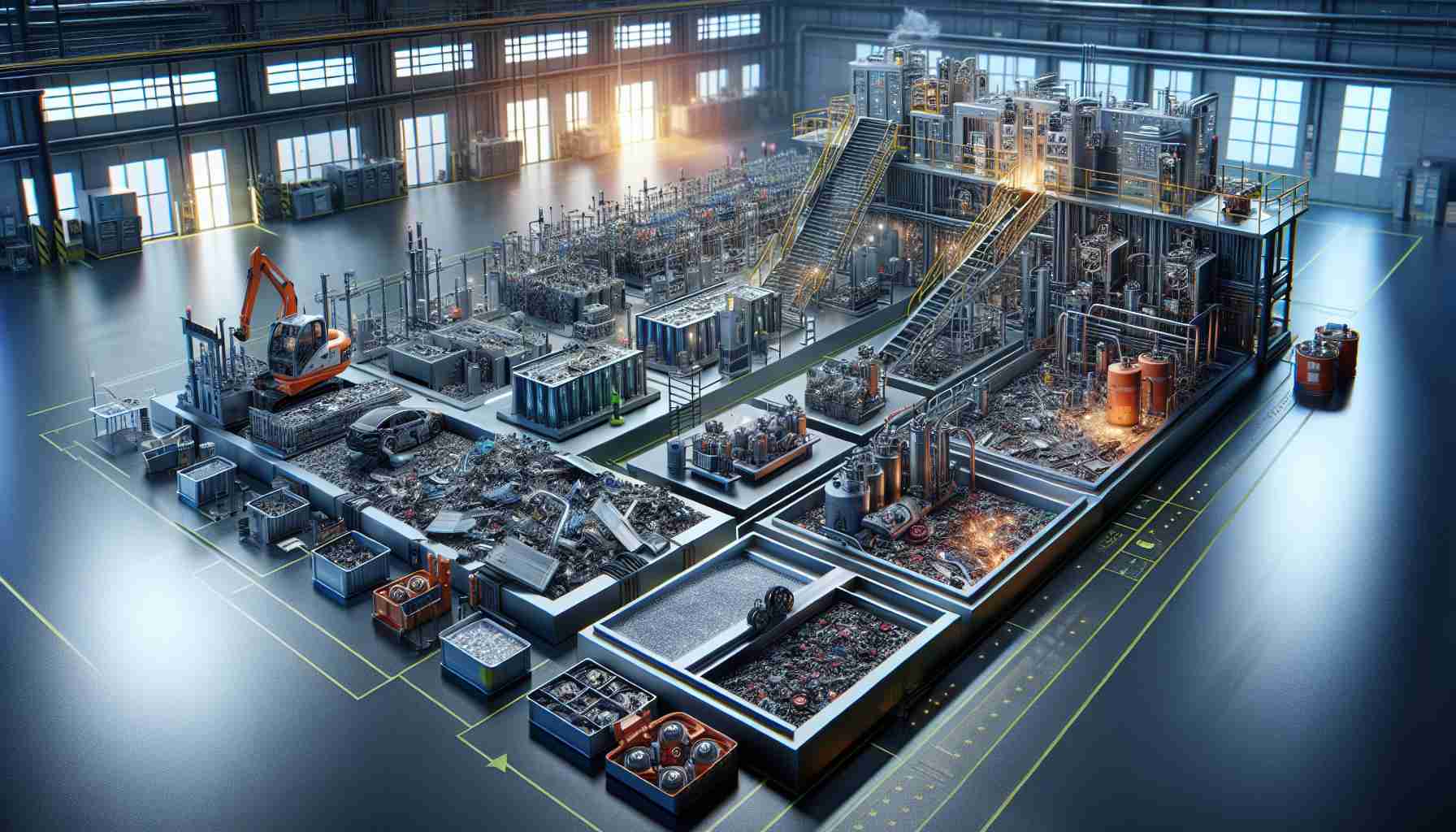

As the UK’s EV market expands, soaring projections show LFP batteries rising from 18% in 2027 to 25% by 2035. This surge underscores an urgent need for effective recycling processes. While the inherent values of iron and phosphate present challenges, Altilium is flipping the script—turning obstacles into stepping stones for green innovation. Their state-of-the-art facility aims to process waste from over 150,000 EVs annually, significantly bolstering the circular battery economy.

This initiative not only addresses the pressing requirement for sustainable battery disposal but also safeguards valuable resources, aligning with escalating regulatory demands for greener practices. Altilium’s mission highlights a powerful takeaway: Recycling is essential not just for environmental preservation but for supporting the future of electric mobility.

Moreover, as the market for LFP batteries grows, Altilium’s efforts are poised to stabilize raw material costs and boost the recycling sector. By closing the loop on resource utilization, they are paving the way to a brighter, cleaner automotive future.

The message is clear: in the race toward electric mobility, sustainable recycling is not merely desirable; it is imperative for a greener tomorrow!

Revolutionizing EV Battery Recycling: How Altilium is Leading the Charge

Introduction to Altilium’s Innovations

Altilium is at the forefront of sustainable practices in the electric vehicle (EV) battery sector, particularly focusing on the recycling of Lithium Iron Phosphate (LFP) batteries. The company’s EcoCathode™ technology stands out, allowing for a remarkable 97% recovery of lithium and 99% recovery of graphite from spent batteries. This innovation is vital as the electric vehicle market continues to expand rapidly, creating a pressing need for effective battery recycling solutions.

Market Projections and Trends

With LFP batteries projected to increase from 18% of the market in 2027 to 25% by 2035, it is evident that efficient recycling operations are more crucial than ever. This growth emphasizes the necessity for Altilium’s operations, which are set to process waste from over 150,000 EVs annually. Such efforts contribute significantly to establishing a circular economy for batteries, which is essential for sustainable development.

Key Benefits of Altilium’s Approach

– Resource Conservation: The technology not only conserves lithium and graphite but also mitigates sourcing challenges for raw materials.

– Environmental Impact: Addressing the problem of discarded batteries is critical for environmental protection, as traditional disposal methods can lead to pollution.

– Economic Stability: By stabilizing the costs of raw materials through recycling, Altilium aids the overall battery industry during periods of fluctuating resource availability.

Insights and Innovations

As Altilium continues to develop its recycling technologies, the company is also focusing on various aspects of sustainability, including:

– Security Aspects: Ensuring that the recycling process is secure and environmentally friendly.

– Market Analysis: Understanding the dynamics of battery supply and demand to align recycling efforts with market needs.

– Sustainability Initiatives: Enhancing the lifecycle of battery components through responsible recycling practices.

Frequently Asked Questions

1. What types of batteries does Altilium recycle?

– Altilium primarily focuses on Lithium Iron Phosphate (LFP) batteries, which are increasingly popular in the electric vehicle market due to their stability and efficiency.

2. How does EcoCathode™ technology work?

– EcoCathode™ technology employs advanced chemical processes to recover high quantities of lithium and graphite from used batteries, minimizing waste and maximizing resource recovery.

3. What is the importance of recycling in the electric vehicle industry?

– Recycling is crucial for reducing environmental impact, conserving natural resources, and supporting the growth of the electric vehicle market by ensuring a steady supply of materials needed for battery production.

Conclusion

Altilium’s groundbreaking efforts in recycling LFP batteries not only promote sustainability but also secure valuable resources for the future of electric mobility. The integration of superior recycling technologies is paving the way towards a greener automotive industry, emphasizing that responsible resource management is vital for long-term success.

For further insights on sustainability in electric vehicles, visit Altilium.